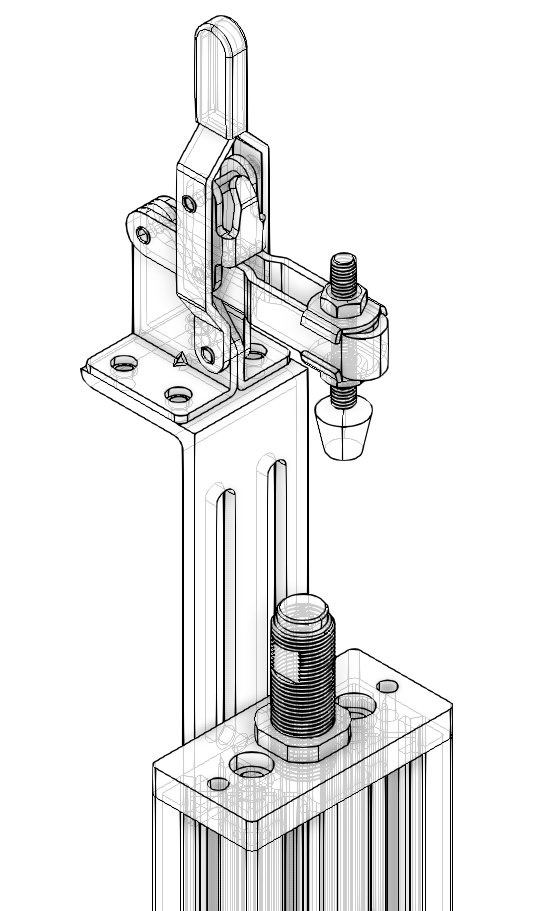

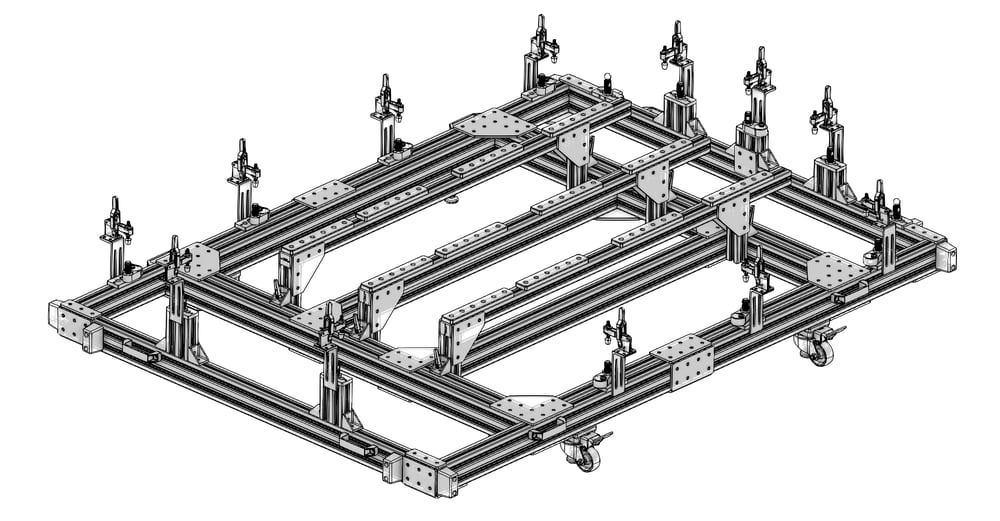

522 the fixture concepts shall accurately show the intent of the design how the part will nest datum locations types of checks clamp locations etc in a manor that is consistent with the geometric dimensioning and tolerancing of. Base plate must fully encapsulated the part and any swing out details in their fully opened position.

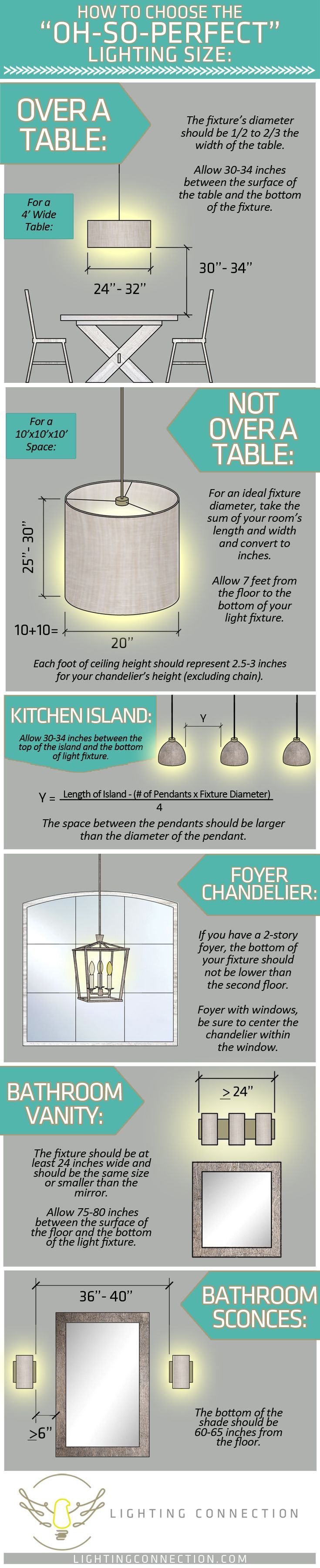

Lighting Size Guide Chandelier Sizing Help Modern Kitchen Lighting Best Kitchen Lighting House Design

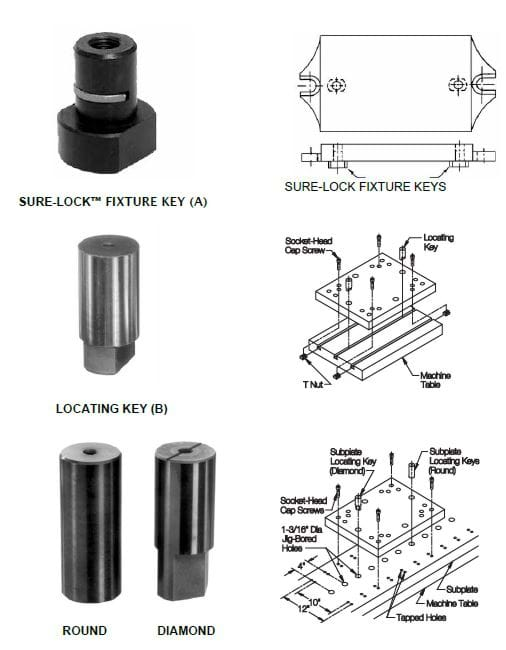

61 All checking or holding fixtures must have 3 Tooling Bushings Tool Balls.

. 80-ENG-D-413 Checking Fixture Gauge Standard 0-07Jul2020. ¾ Check fixture less than 10 lbs requires no feet check fixture 10-30 lbs requires feet and a check fixture more than 30 lbs requires 2 high risers. Checking fixtures are designed for accuracy repeatability and reliability with a strong focus on operator ergonomics.

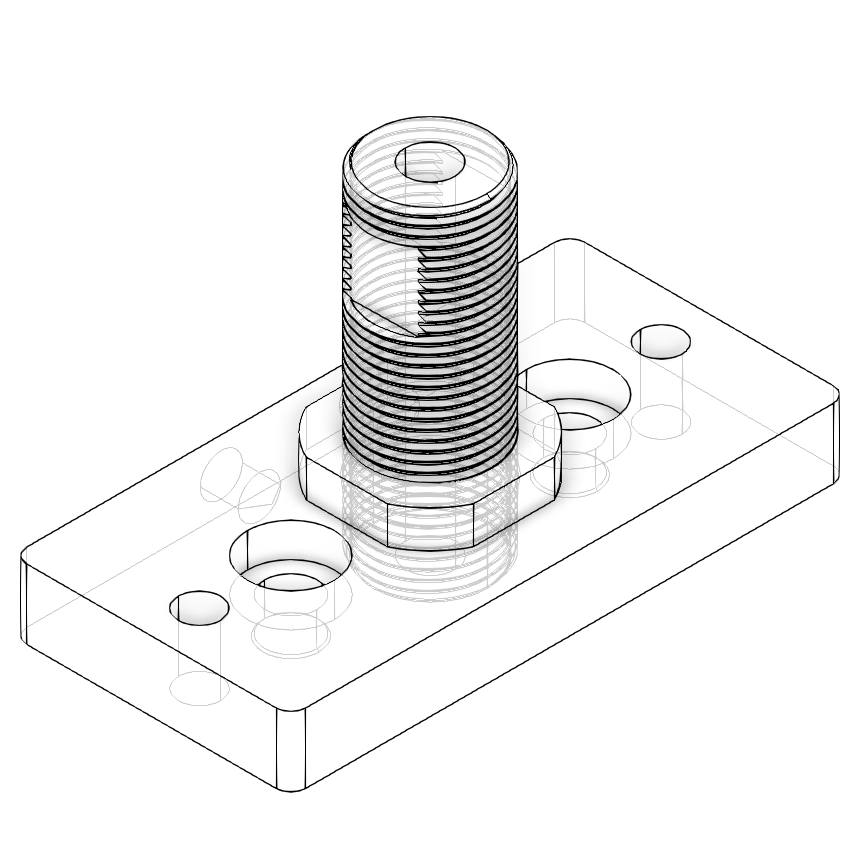

Factors to be considered for design of Jigs and Fixtures 1. 511 All check Fixtures are to be quoted as design and build. Base plate to be constructed of aluminum 1 thick with machined edges parallel to body or work lines and machined numerals as per location.

The des ign and creation of the 2D and 3D of the project. The precision measurements obtained with a checking fixture ensure control of part dimensions for mass production. Checking fixture is one of the inspection tools used in most of the industries in order to scale the measures of products with complicated shapes.

Checking fixture design guidelines Written By arethaquain36025 Friday. The definition of a checking fixture will have important consequences on. This Network Rail standard specifies the requirements for the design and construction of track with line speeds up to 125 mph.

Checking fixture design guidelines Written By marcmassaquoi341 Saturday June 11 2022 Add Comment Edit. The checking fixture is a convenient tool used by industrial production companies to control the dimensions of auto parts such as trim edgesurface profile hole size flatness etc it is suitable for mass production of parts. Compliance to these requirements is mandatory for all involved parties.

62 In the absence of a qualified stamped base checking fixtures are to be provided with three tooling. The check fixture is a form of gage. Design of fixture checking including Position of hole and slot.

This alignment can be geometric or by 3 centres. Using this a formal generalization of the concepts and methodologies of fixture design for Tinker will be developed. But how can you manage a holiday with a baby and all her gear in tow.

The materials to be used the elements of metrology to be included and the surface and heat treatments. 62 In the absence of a qualified stamped base checking fixtures are to be provided with three tooling. Standard size of sphere to be 120 mm in diameter and 120 mm distance from center to shoulder mounted on base or on a 50 x 50 x 13 mm block.

4 of them are engineers with the related working experiences for minimum 5 years. If the base plate exceeds 60 in length the location of the tapped holes should be 600mm from the center in both direction. 114 Fixture Design Fundamentals.

They ensure repeatability accuracy and reliability for parts with often complicated geometries. Design verification is the most important aspect of the product development process illustrated in Figures 13 and 15 consuming as much as 80 of the total product development timeThe intent is to verify that the design meets the system. Checking fixtures are an essential measuring tool in the production process.

Base plate must fully encapsulated the part and any swing out details in their fully opened position. Most of the manufacturing companies use checking. Checking Fixture Design Guidelines.

Today this process is primarily handled with advanced technology like CNC machines. 521 fixture concept must be submitted to bae within one week after kick off of any new check fixture. E t The manufa cture of every lemen of the checking fixture.

All checking fixtures must have four tapped holes M16 present on the base plate. Especially in automotive work check fixtures or checking aids as they are referred to in the PPAP process often are a hybrid of the two. Up to 24 cash back Checking fixture design guidelines.

Using checking fixtures in the right stage of process can. The Jigs and fixtures design as well as the clamping support and locating technique of your machine setup must work in tandem to create flawless products or prototypes. This document is intended as a guideline to make fixture sources aware of the build requirements and buyoff criteria that will provide the basis for fixture approval and invoice payment.

Testing ICT is an example of white box testing where an electrical probe tests a populated printed circuit board PCB checking for shorts opens resistance capacitance and other basic quantities which will show whether the assembly was correctly fabricated. Jigs and fixtures have an undeniable role in the overall art of metalworking. 62 In the absence of a qualified stamped base checking fixtures are to be provided with three tooling.

A check fixture differs from a jig in that the jig is essentially a holding device to hold the piece part while work or inspection is performed. Specific constraints for each shop will again be identified. Phase I 2 actual practical development at Tinker will be drawn.

This paper prese nted a fixture layout design shown in fig. Hence a step-by-step procedure for jig and fixture design will be developed. Checking fixture design guidelines Written By louiezoldak24685 Friday April 22 2022 Add Comment Edit If the checking fixture were to exceed the CMM table size additional feet will be needed to sit level.

Designing Jigs And Fixtures Design Guide Vention

Principles Of Location In Jig Fixture Design Carr Lane

What Is Jig Fixture Design Carr Lane Mfg Co

Designing Fixtures Tech Tip Youtube

Design Principles Of Jigs And Fixtures Prescient Technologies

0 comments

Post a Comment